- We shall consider that collotype on glass is the most practical. It ensues from simple observations which we can doing during visit of studios still in service which use it all. Collotype on copper having disappeared. It thus seems that glass plates is best, for many reasons,Whose most likely are the price.

- Be that as it may, no matter, because the process does not really depend on its support, but really on preparation of operations and because glass relatively well meets requirements of process, with adapted preparation. We shall not thus return on the copper as the support (refer to the former books on this subject).

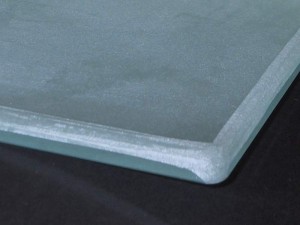

- The thickness of glass plates to be used is usually 10 mm, but can be more thick for them very large formats. Do not use glass below 8 mm in thickness, the too fine glass

risking to break under pressure during the edition. They have to be of size superior to picture. As a general rule, a minimal margin of 5 cms is left between the edge of image and the edge of glass, this for landing in defect that the edges of the sensitive coat can present (bound to the casting of this coat), as well as in the inevitable imperfections of the wetting of the edges of the plate during the preparatory operations to the edition. Choose clear ordinary glass, but without scratch.

risking to break under pressure during the edition. They have to be of size superior to picture. As a general rule, a minimal margin of 5 cms is left between the edge of image and the edge of glass, this for landing in defect that the edges of the sensitive coat can present (bound to the casting of this coat), as well as in the inevitable imperfections of the wetting of the edges of the plate during the preparatory operations to the edition. Choose clear ordinary glass, but without scratch.

The superior edges of glass are rather rounded off by grinding (with water) made by means of a marbler’s portable grindstone (to make realize by a specialist, the operation being delicate). For lack of grinding, use a file in materials high hardness. The roundings have to present a textured surface, also allowing the grip of the sensitive coat, quite as on the top. The round edges allow to avoid that one on thickness of gelatin occurs in periphery of the surface of theglass when

The superior edges of glass are rather rounded off by grinding (with water) made by means of a marbler’s portable grindstone (to make realize by a specialist, the operation being delicate). For lack of grinding, use a file in materials high hardness. The roundings have to present a textured surface, also allowing the grip of the sensitive coat, quite as on the top. The round edges allow to avoid that one on thickness of gelatin occurs in periphery of the surface of theglass when  the sensitive coat is poured, by the simple effect of capillarity. Furthermore, the angle left lively at the edge of glass always risks to damage ink rolls. However, certain practitioners simply rounding off hardly angles and stop in passing a simple abrasive paper to cut stop them, considering that it is useless to round more edges for the editions with shims (what is always the case during the editions with the press with cylinder).

the sensitive coat is poured, by the simple effect of capillarity. Furthermore, the angle left lively at the edge of glass always risks to damage ink rolls. However, certain practitioners simply rounding off hardly angles and stop in passing a simple abrasive paper to cut stop them, considering that it is useless to round more edges for the editions with shims (what is always the case during the editions with the press with cylinder).